A set of chuck jaws would do just as well, and be easier to use. I was thinking of printing out some single-use collets, jut bore, trim off the nose (that keeps the slits apart), and use as needed. Move a Model Choose the model and click the Move button. Once it was all figured out, it would be near zero effort to print out another set for whatever. Maybe leave them a little snug in the slides to they're easy to bore out to whatever size is needed. JonCan't say as I'd be worth the effort to print out a whole chuck. Oh, another benefit of PETG, superior layer adhesion Thanks to Durwin Pye for cleaning the scad. I work with plastic injection molding and we occasionally like to have a. Accuracy and finish and are my main attributes I need in a printer.

If I can tidy it up I will post at a latter date-DONE I will be buying my first 3d printer and a friend of mine who has some experience in 3d printing is telling me that a Cetus 3D printer is the perfect option for my needs. I have not included the Scad file at the moment, as it is a real mess, Thanks to MrArrow1961 for the reverse jaws /thing:624814 3rd, ok but tend to over tighten, which could break the scroll This offer can bring really nice savings to you. Now this definitely isnt the best Benchy Ive gotten off my Cetus, there are more than a few small issues, but its the only one Ive printed so far with S3D. According to statistics, a person who participated in Up to 35 off Add-Ons saved an average of 24.98. I initially was having the same issue last night, then I busted out the caliper and saw that the sample Cetus filament was measuring 1.65mm So adjusted that in Simplif圓D and got better results. I have printed and tested (sort of) different jaw materials And added photosįlexi at 85% infill. Save up to 30 OFF with Cetus 3D Coupons and Coupon Codes. Parametric Involute Bevel and Spur Gears by GregFrost

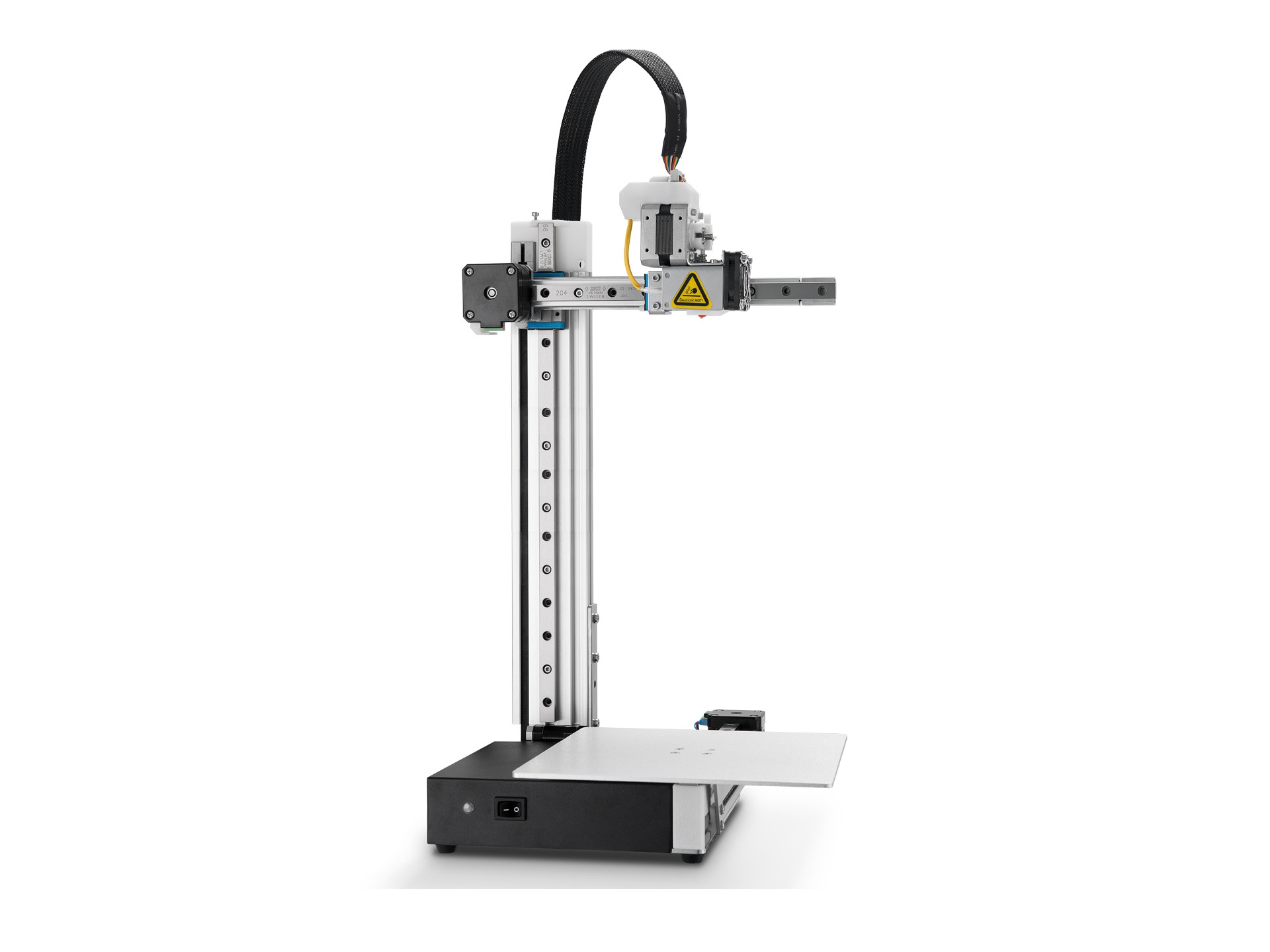

MEASURE SOMETHING IN CETUS3D PLUS

I have added it to the list of files -not for the faint of heart-Īfter printing some other designs and finding they did not work for me, I decided to have a go myself, So here it is, Please beware, I have made allowances for my own printer so I take no resonsibility if it doesnt work for you.Īlso, to state the obvious, this is a plastic chuck, it has its limits!.ġ01mm diameter, 59mm thick plus 25mm jaw height. Durwin Pye has sorted out the Scad file so it is now brilliant, Thanks,

0 kommentar(er)

0 kommentar(er)